Diecasting has actually become an important part of Malaysia’s manufacturing sector, supporting key sectors like automobile, electronics, and industrial equipment. The procedure, which involves infusing smelted metallic right into a mold under higher pressure, allows makers to produce durable and specific elements in huge volumes. Along with the country’s well-established commercial infrastructure and proficient staff, Malaysia has placed itself as an affordable hub for Diecasting manufacturing. The sector perks coming from present day establishments, groundbreaking innovations, as well as strict high quality management procedures that meet global manufacturing requirements. Many global firms have chosen Malaysia as a calculated site for their Diecasting procedures as a result of its own economical development abilities and also access to significant markets. As the requirement for light-weight and high-strength metal parts continues to climb, Malaysia’s Diecasting sector is actually expected to broaden better, contributing dramatically to the country’s economic growth.

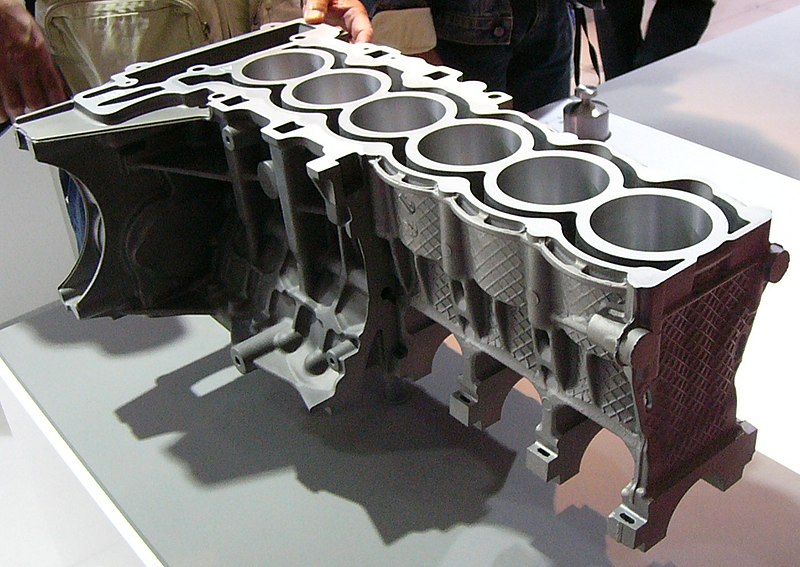

The auto sector is just one of the biggest consumers of die-cast parts, as well as Malaysia plays a vital role in offering high-grade metallic parts for lorries. Diecasting is actually largely used in the manufacturing of engine blocks, gear box instances, as well as architectural parts that demand both toughness and light in weight homes. Along with the growing emphasis on gas efficiency as well as electrical cars, vehicle producers are significantly counting on light weight aluminum die directing to lower the body weight of their vehicles. Malaysian Diecasting companies are known for their ability to generate intricate motor vehicle dispose of higher preciseness, sticking to international high quality certifications including ISO 9001 and IATF 16949. A lot of local area agencies have likewise made up alliances with global car makers, enabling all of them to export their products to markets in Europe, the United States, as well as Asia. The ongoing improvements in automotive engineering and also the change towards maintainable mobility remedies will definitely additionally drive demand for die-cast parts in Malaysia.

Beyond the auto field, the electronic devices and telecommunications business greatly depend on Diecasting for the manufacturing of accuracy metal parts. Malaysia has developed on its own as a leading center for electronic devices manufacturing, with several global companies putting together production centers in the country. Die-cast parts are vital for various digital devices, including smartphones, laptop computers, as well as home devices, along with for commercial equipment including electrical power source units as well as network structure. The ability to create intricate styles with tight resistances helps make Diecasting an ideal production technique for these uses. To stay up to date with the hectic electronic devices industry, Malaysian Diecasting firms have adopted stressful Diecasting (HPDC) as well as computer-aided design (COMPUTER-AIDED-DESIGN) modern technologies to improve precision as well as productivity. As buyer requirement for sophisticated electronic tools carries on to increase, Malaysia’s Diecasting sector is actually poised to assist the enhancing requirement for trustworthy and top quality components.

The durable goods and commercial machines fields likewise profit from Malaysia’s robust Diecasting field, as producers require long lasting and also economical metallic parts for various uses. House home appliances, electrical power devices, and also mechanical tools often combine die-cast aluminum or zinc elements to enhance their durability as well as endurance. Many Malaysian Diecasting firms work very closely with developers as well as designers to establish customized services that satisfy details field requirements. Making use of innovative creating approaches and automated production devices has assisted makers improve outcome while maintaining item high quality. With Malaysia’s solid source establishment system and dependable strategies commercial infrastructure, neighborhood Diecasting companies can successfully supply components to domestic as well as worldwide markets. As fields remain to look for ingenious ways to enrich item efficiency and decrease production prices, the need for die-cast services is actually expected to remain sturdy. For more information please visit here Senadiecasting

Sustainability has become an expanding focus in Malaysia’s Diecasting business, along with firms making every effort to apply green methods. Many makers are acquiring energy-efficient equipment, using reusing projects, and maximizing development processes to reduce component refuse. Making use of light-weight steels including light weight aluminum not only advantages sectors trying to minimize their carbon dioxide footprint but also straightens with international efforts to market maintainable manufacturing. In addition, Malaysia’s federal government has offered initiatives to encourage eco-friendly modern technologies and also Sector 4.0 innovations, additionally sustaining the embracement of environment-friendly Diecasting processes. By integrating smart production technologies, including real-time monitoring as well as anticipating servicing, Diecasting organizations may improve productivity while lessening ecological influence. These lasting techniques ensure that Malaysia’s Diecasting industry continues to be affordable and associated along with worldwide criteria.

Looking ahead, the future of Diecasting in Malaysia appears appealing as the business remains to develop with developments in hands free operation, robotics, as well as material advancements. The integration of artificial cleverness (AI) and also electronic paired innovation is actually assumed to improve method optimization and quality assurance, leading to even more significant precision in manufacturing. As worldwide need for high-performance metallic parts proceeds to rise, Malaysia is well-positioned to enhance its own role as a leading Diecasting center in Asia. The combo of solid federal government support, competent effort, and also ongoing technological renovations will certainly drive additional growth in the market. Along with a dedication to development and durability, Malaysia’s Diecasting industry is actually specified to remain a vital factor to the nation’s production landscape, offering high-grade solutions to markets worldwide.