Die casting has become a critical component of Malaysia’s manufacturing landscape, driving innovation and supporting the nation’s industrial growth. This metal casting process involves forcing molten metal into a mold cavity under high pressure, producing precision components with exceptional durability and detail. Malaysia’s strategic location in Southeast Asia, combined with its advanced manufacturing infrastructure, has made it a hub for die casting production. The industry caters to a variety of sectors, including automotive, electronics, and aerospace, where high-quality metal components are essential. As global demand for precision engineering rises, Malaysia continues to strengthen its position as a leader in the die casting industry.

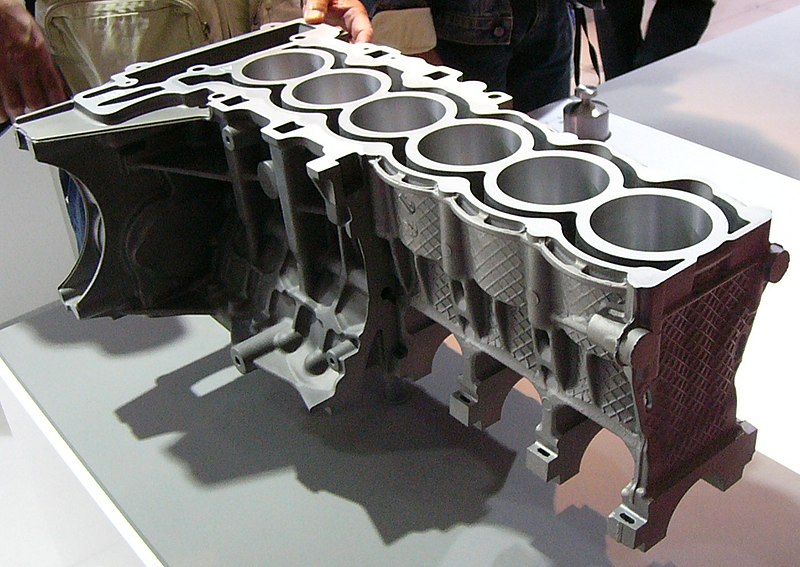

The automotive industry in Malaysia is one of the largest consumers of die-cast components, benefiting from the process’s ability to produce lightweight yet strong parts. Aluminum die casting, in particular, is widely used to manufacture engine components, transmission cases, and structural elements that reduce vehicle weight without compromising strength. This focus on lightweight materials is vital for improving fuel efficiency and reducing carbon emissions, aligning with the global push for sustainable practices. Malaysian manufacturers have invested in state-of-the-art die casting technologies to meet the stringent quality and efficiency standards demanded by the automotive industry, making the country a key player in the global supply chain.

Electronics and telecommunications are other sectors that rely heavily on die casting in Malaysia. The process is ideal for producing heat sinks, housings, and other intricate components that require precision and thermal conductivity. As Malaysia is a prominent exporter of electronic goods, the die casting industry plays a vital role in supporting this sector’s competitiveness. Manufacturers leverage advanced techniques such as multi-slide die casting and CNC machining to produce components with tight tolerances and complex geometries. These capabilities allow Malaysian companies to meet the high standards of global clients, further cementing the country’s reputation for quality and reliability in manufacturing.

Sustainability is increasingly becoming a focus within aluminum die casting Malaysia industry, driven by the need to balance environmental considerations with industrial growth. Many manufacturers are adopting energy-efficient technologies and recycling practices to minimize waste and reduce their carbon footprint. The use of recyclable materials like aluminum and magnesium aligns with these efforts, as these metals can be reused without losing their properties. Additionally, modern die casting methods have been optimized to use less material while maintaining product strength, contributing to the overall sustainability of the process. By embracing these eco-friendly practices, Malaysia is positioning itself as a responsible leader in the global manufacturing sector.

Innovation and technological advancements are at the core of Malaysia’s success in die casting. Local companies are integrating automation, robotics, and data-driven solutions to enhance efficiency and precision in the production process. Industry 4.0 technologies, such as IoT and predictive maintenance systems, are also being adopted to improve operational reliability and reduce downtime. These advancements not only increase production capacity but also enable manufacturers to meet the evolving demands of clients in a highly competitive market. Through government support and private sector initiatives, Malaysia continues to build a robust ecosystem that fosters innovation and encourages investment in the die casting industry.

Die casting is a cornerstone of Malaysia’s industrial success, providing the foundation for growth in key sectors like automotive, electronics, and telecommunications. With its focus on precision, sustainability, and technological innovation, Malaysia has emerged as a global leader in this critical manufacturing process. The country’s commitment to quality, efficiency, and environmental responsibility ensures that its die casting industry will remain competitive in the face of rising global demand. As Malaysia continues to invest in advanced technologies and sustainable practices, its position as a hub for die casting excellence is set to grow even stronger, contributing to both local and international industrial development.